|

Lianyungang Yuanda Quartz Product Co.,Ltd

|

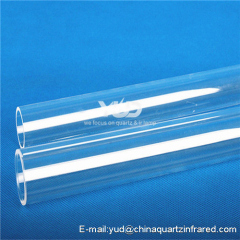

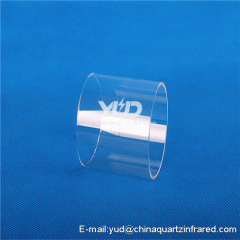

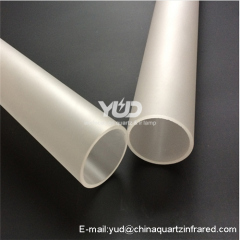

Double Deck Silica Quartz Glass Tube Durable and transparent easy to clean

| Price: | 8.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

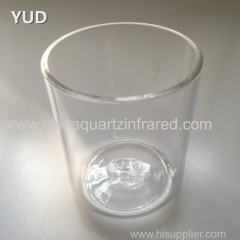

1.Double Deck Silica Quartz Glass Tube

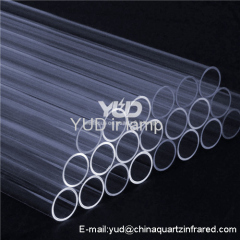

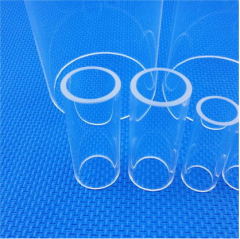

2.High Quality Quartz Glass Tube

3.Heat Resistant Fused Silica Quartz Glass Tube For Semiconductor

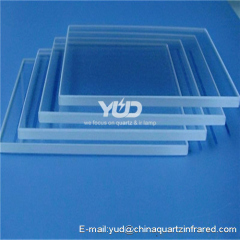

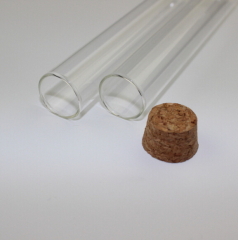

High temperature resistant further processing quartz tube with cover for sale

Double Deck Silica Quartz Glass Tube

All kinds of high quality quartz tube

Accept the sample order, also could customize based on the drawing.

Overview

Quick Details

Place of Origin:

China (Mainland)

Brand Name:

YUD

Model Number:

Quartz Tube

Type:

Clear Quartz Pipe

Color:

Transparent or Opaque,Clear and transparent

Application:

Chemical industry, heater and light field

Surface Treatment:

Polished

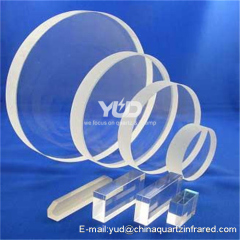

Outside Diameter:

3-300mm

Ozone Content:

Ozone Free

Density:

2.2g/cm3

Size:

Customized

Purity:

99.99%

Wall Thickness:

1mm-5.0mm

Length:

100mm-2500mm

Packaging & Delivery

Packaging DetailsInner White foam paper+ Plastic foam sheet ,Outside with wooden

Delivery Time In 7-15 days after we received the deposit

Product Description

clear thick wall high temperature quartz tube for tube furnace clear fused quartz glass tube available as continuous machine drawn and automatic controlled tubing .this glass has the typical characteriastics of high purity ,good spectral transmission,well controlled dimension and lower OH and so on .it serves as the first choice of heat resistant material for halogen lamps ,mercury lamps ,metal halide lamps and other quartz lamps .this glass can be supplied in the range of 3-300mm outside diameter,1.0-5.0mm wall thickness and 100-2500mm length. Exhaust tube with good CPK are suiable for highspeed streamline production .and further processing of trim cutting ,fire polishing ,bending and pinchingcan be done according to the requirement of cusomers .OH-content can be controlled within 20ppm/15ppm/10ppm/5ppm/2ppm according to the requirement of customers.

Physical properity:

| SiO2 | 99.997% |

| Density :(g/cm3) | 2.2 |

| Degree of hardness moh' scale (Pa) | 6.6 |

| Melting point: | 1732°C |

| Working temperature : | 1100°C |

| Max temperature can reach in a short time : | 1450°C |

| Tolerance: | 30 times than Ceramics,150 times than stainless steel |

| Visible light transmittance: | above 93% |

| UV spectral region transmittance: | 80% |

| Resistance value: | 10000 times than ordinary glass |

| Annealing point: | 1180°C |

| Softening point: | 1630°C |

| Strain point: | 1100°C |

Diamension:

IDxOD (mm) | Thickness (mm) | IDxOD (mm) | Thickness (mm) | IDxOD (mm) | Thickness (mm) |

1x3 | 1 | 10.5x12.75 | 1.13 | 30x33 | 1.5 |

1.2x3 | 0.09 | 11x13 | 1 | 32x35 | 1.5 |

1.6x3 | 0.7 | 11.7x14.1 | 1.2 | 34x28 | 2 |

2x3 | 0.5 | 12x14 | 1 | 35x38 | 1.5 |

2x4 | 1 | 12.75x15 | 1.13 | 37x40 | 1.5 |

2x6 | 2 | 13x15 | 1 | 38x44 | 3 |

2.3x2.6 | 0.6 | 15x17 | 1 | 38.1x42.1 | 2 |

2.35x3.65 | 0.65 | 15x18 | 1.5 | 40x43 | 1.5 |

2.35x4 | 0.83 | 16x18 | 1 | 42x45 | 1.5 |

2.35x4.35 | 1 | 18x20.5 | 1.25 | 45x48 | 1.5 |

3x5 | 1 | 18x21.6 | 1.8 | 47x50 | 1.5 |

4x6 | 1 | 19x25 | 3 | 48x52 | 2 |

5x7 | 1 | 20x25 | 1 | 50x54 | 2 |

6x8 | 1 | 20x22.8 | 1.4 | 50x55 | 2.5 |

6x10 | 2 | 20x23 | 1.5 | 53x57 | 2 |

7x9 | 1 | 20.2x23 | 1.4 | 55x59 | 2 |

7.75x9.75 | 1 | 22x25 | 1.5 | 57x61 | 2 |

7.8x10 | 1 | 22x25.3 | 1.65 | 60x64 | 2 |

8x10 | 1 | 22x25.8 | 1.9 | 63x67 | 2 |

8x12 | 2 | 23x26 | 1.5 | 65x69 | 2 |

8.5x10.5 | 1 | 25x27.5 | 1.25 | 66x70 | 2 |

9x11 | 1 | 25x28 | 1.5 | 68x72 | 2 |

9x11.8 | 1 | 25x28.8 | 1 | 70x80 | 2.5 |

10x12 | 1 | 27x30 | 1.5 | Ect |

Dimensional Tolerance

Range of OD | OD | WT | Siding | Out of Round | Bow\1220mm |

≤6mm | ±2.0% | ±10% | 12% | 2.00% | 2.5mm |

6.00-15.00mm | ±1.25% | ±8% | 10% | 1.50% | 2.5mm |

15.00-20.00mm | ±1.25% | ±10% | 15% | 1.50% | 2.5mm |

20.00-25.00mm | ±1.25% | ±10% | 15% | 1.50% | 3.0mm |

25.00-30.00mm | ±1.35% | ±12% | 15% | 1.5% | 3.0mm |

30.00-80.00mm | ±1.5% | ±14% | 15% | 2.00% | 3.0mm |

80.00-100.00mm | ±1.0% | ±0.5mm | 15% | 2.00% | 3.0mm |

100.00-120.00 | ±1.5% | ±0.8mm | 15% | 2.00% | 3.0mm |

120.00-160.00 | ±1.8% | ±1.0mm | 20% | 2.50% | 3.0mm |

160.00-180.00 | ±3.0% | ±1.0mm | 25% | 2.50% | 3.0mm |

180.00-200.00 | ±4.0% | ±1.5mm | 25% | 2.50% | 3.0mm |

200.00-240.00 | ±4.0% | ±1.5mm | 25% | 2.50% | 3.0mm |

240.00-280.00 | ±6.0% | ±2.0mm | 25% | 2.50% | 3.0mm |

280.00 above | ±8.0% | ±3.0mm | 25% | 2.50% | 3.0mm |

Chemical Composition(ug/g)

Cr | Ge | Fe | Mg | Ti | Ga | Al | Na | Li | K |

0.1 | 0.4 | 1.5 | 0.4 | 0.1 | 0.8 | 16 | 2.3 | 0.5 | 2 |

Application :

This product is mainly used in electric light source, electrical appliances (electric), semiconductor, optical communications, military industry, metallurgy, building materials, chemical, machinery, electricity, environmental protection and other fields.

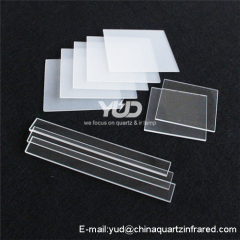

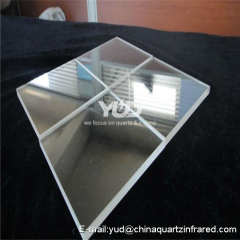

Products Show

FAQ

What are the advantages of Quartz glass tube?

1.High purity made of 99.99%-99.9999% pure quartz.

2.Strong Hardness, Can reach Morse level 7.

3.High temperature resistance, can work under 1200°C continuously,and in short time can even work under 1500°C.

4. The stability is 30 times of the ceramic, and 150 times of stainless steel

5. Electric insulation, it is 10000 times of usual glass.

6. High light transmittance , it is different from 85%-95% depend on different spectrum.

7.Excellent thermal shock stability ,Small thermal expansion coefficient,it is only 5.5×10-7/℃

8.control in less than 20 PPM, 15 PPM, 10 PPM, 5 PPM ,2 PPM.

Why choose US ?

1. 11 years experiences on glass manufacturing and exporting.

2. Top quality glass with CE,CCC certificate, exporting to more 80 countries in the world.

3. Unique designed strong wooden cases, solving the problems of breakage.

4. Dockside warehouses beside three of China main container seaports, ensuring convenient loading and rapid delivery.

5. Full range of flat glass supply, offering one-stop purchase.

6. Professional sales team, offering personalized and dedicated services.

How to order:

Step1 Please choose the goods with links or pictures which you want to order, Then click contact supplier or chat with me Or just send an inquiry. When we get your inquiry, we will give you a quotation soon within 24hours.

Step2 You can email us your order list with details, we'll reply right away when we received your email.

Send your inquiry Details in the Below for free sample,Click "Send"now.

Certificate:

Contact:

Contact:

Welcome to contact with me in any time !